A consortium led by @Airbus has successfully conducted the first metal 3D printing on the International Space Station (ISS). The historic event took place on Thursday, May 30, when the printer created a small S-shaped curve using liquefied stainless steel. The @European Space Agency believes this test demonstrates the printer’s readiness to start manufacturing usable materials in the near future.

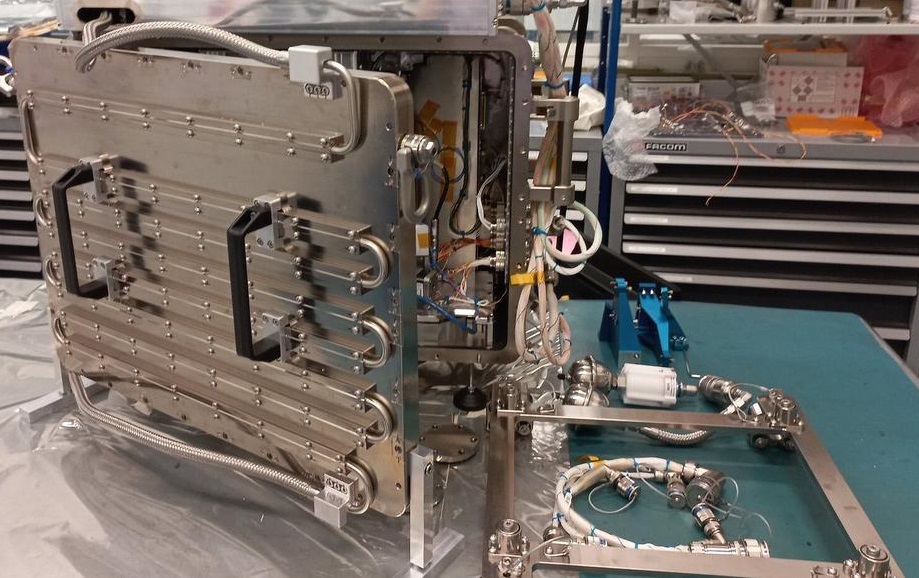

The metal 3D printer, weighing approximately 180 kg (396 lbs), arrived at the ISS on January 30 this year, launched aboard a SpaceX Falcon 9 rocket as part of the Cygnus NG-20 mission. While plastic-based 3D printers have been used on the ISS before, metal 3D printing poses unique challenges due to the high temperatures required to liquefy metals. To address this, the metal printer is housed in a fully sealed box, preventing excess heat and fumes from escaping.

The metal 3D printer operates by feeding stainless-steel wire into a chamber, where it is heated by a high-power laser, melting the steel and allowing it to be shaped by the printer. The entire process is controlled from the ground, with the ISS crew only responsible for opening a nitrogen and venting valve before the test.

The next step involves using the printer to create four shapes that will be sent back to Earth for analysis. Two of these printed parts will undergo examination at the Materials and Electrical Components Laboratory at @ESTEC in the Netherlands to determine if prolonged microgravity affects the printing of metallic materials.

This milestone in metal 3D printing on the ISS marks a significant step towards creating a circular economy in space using such printers. The technology could support long-term space missions by reducing the need for resupply missions and enabling the production of spare parts on-demand. However, challenges such as the need for specialized materials and the impact of microgravity on the printing process must be addressed to fully realize the potential of this technology in space.