The future of space exploration is being reshaped by innovative technologies, with 3D printing at the forefront. This transformative approach to manufacturing is poised to revolutionize how we build and maintain parts and structures in space, offering unprecedented flexibility and efficiency.

3D printing, also known as Additive Manufacturing, is a process that builds objects layer by layer until the desired shape is formed. Originally used primarily for prototyping, it has evolved into a powerful tool for making components as needed quickly.

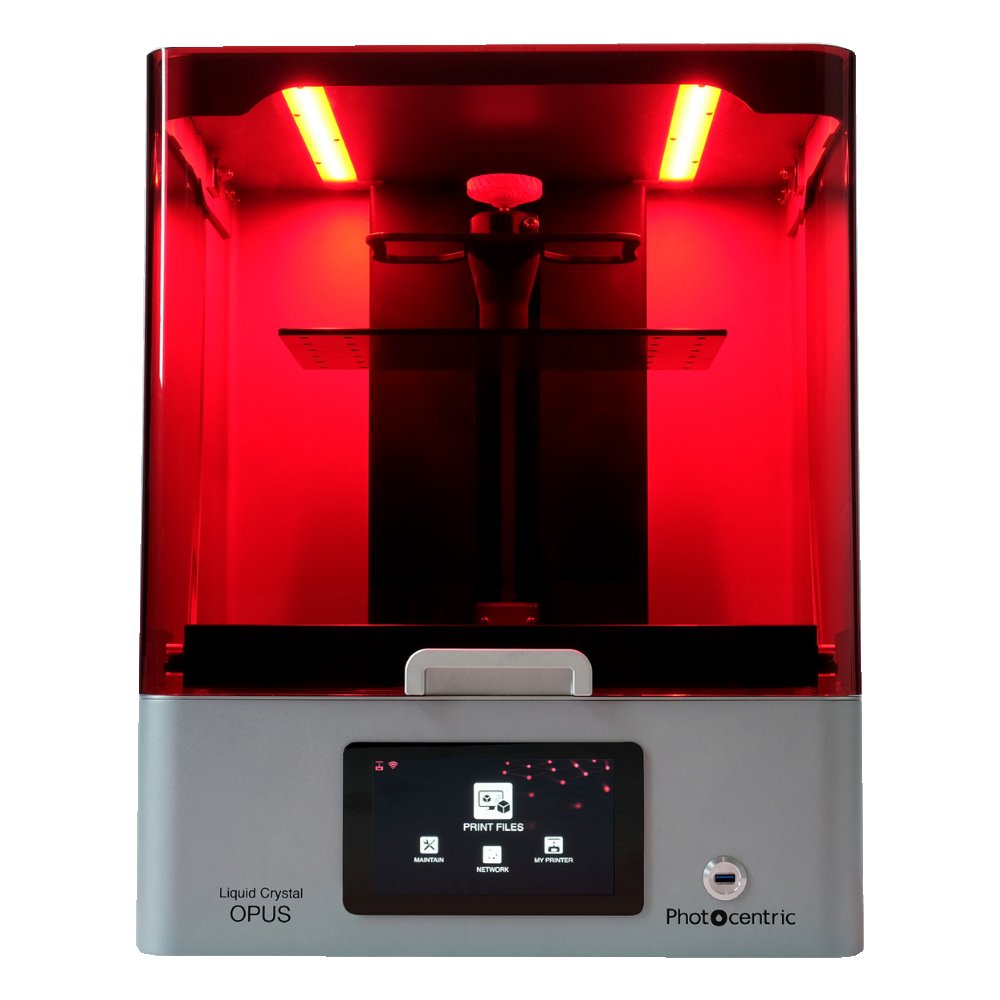

The Business in Space Growth Network (BSGN) In-orbit Manufacturing Accelerator (IMA), led by @Satellite Applications Catapult, is supporting @Photocentric, a UK-based additive manufacturing innovator, on the development of CosmicMaker – a patented LCD-based 3D printer. The technology is capable of additively manufacturing intricate functional parts from Silicon Carbide.

What sets Photocentric’s LCD-based 3D printing apart is its unique approach to layer creation. Using an LCD screen as a light source, an entire layer is encoded simultaneously, rather than small area by area. Photocentric, the inventor of LCD 3D printing, has patented an enclosed chamber form of LCD printing that is both gravity and pressure independent. This process is remarkably robust, capable of functioning even if the printing system is in any orientation, subjected to shaking or shocks, or exposed to elevated or lowered temperatures. The technology is very light, modular, scalable, and repairable, making it ideal for space applications.

CosmicMaker printed components are expected to address critical space applications such as thermal management parts, radiation shielding, electronic components, and structural elements for space stations and future planetary missions. Moreover, this technology opens up exciting possibilities for sustainable space exploration. Raw materials required for 3D printing could potentially be extracted from planetary surfaces, reducing the need for Earth-launched supplies. This breakthrough could lead to truly self-sustaining missions where robots could print their own spare parts to continue their tasks, dramatically extending the reach and duration of space exploration missions.

While the potential for 3D printing in space is exciting, it’s worth noting that this technology is already making waves on Earth. In various industries, from aerospace to healthcare, 3D printing is being used to create complex parts, and even produce medical implants. The lessons learned from terrestrial applications are informing space-based developments, and vice versa, creating a symbiotic relationship that drives innovation in both realms.